What were the development for inductor manufacturing in the last decade? Give me an account of the development, milestones and it's interaction with the market demand, change in its size, material and other characteristics as a result this interaction with suppliers, market and technology.

In the last decade, there have been several notable developments in inductor manufacturing, driven by market demands, technological advancements, and the need for smaller, more efficient components. Here's an account of some key developments and milestones:

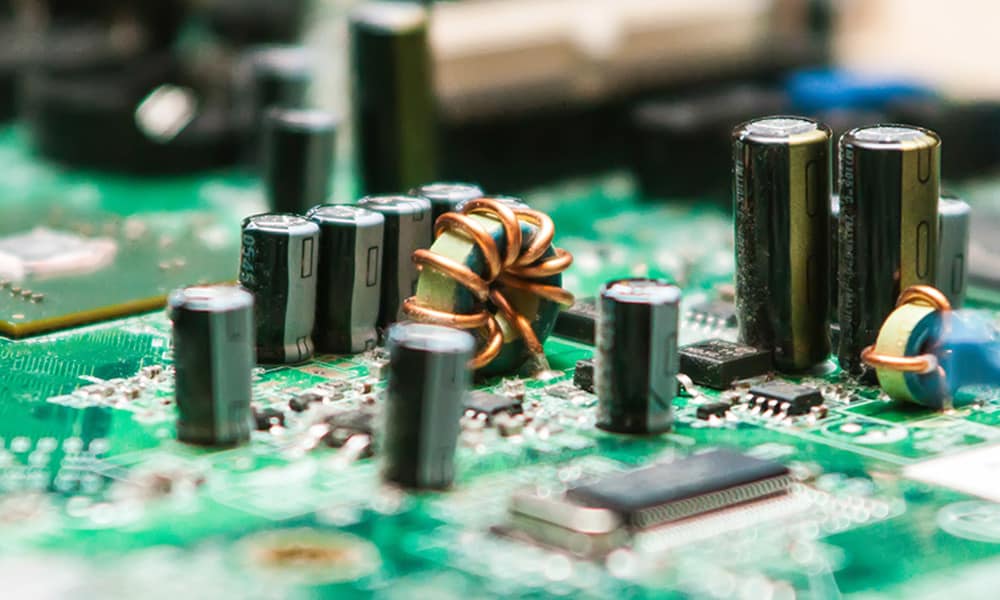

Miniaturization and Size Reduction: There has been a significant push towards miniaturization of inductors to meet the demands of portable devices, wearables, and IoT applications. Manufacturers have focused on reducing the size of inductors while maintaining or improving their performance. This has led to the development of smaller surface mount technology (SMT) inductors, such as chip inductors, with compact dimensions and high-density packaging.

Advanced Core Materials: New core materials have been introduced to enhance the performance of inductors. For example, high-flux magnetic materials, such as ferrite composites and nanocrystalline cores, offer improved magnetic properties, higher saturation levels, and reduced core losses. These advanced materials enable inductors to handle higher currents, operate at higher frequencies, and provide better overall efficiency.

Integration of Shielding: As electromagnetic interference (EMI) becomes a growing concern in electronic systems, there has been an increased demand for shielded inductors. Manufacturers have developed inductors with integrated shielding to minimize EMI and prevent cross-talk between components. This integration simplifies the design process and reduces the need for additional shielding components.

Customization and Application-Specific Designs: With the diverse range of applications, there has been a greater emphasis on customization and application-specific inductor designs. Manufacturers now offer inductors tailored to specific requirements, such as high-frequency applications, automotive electronics, power management, and wireless charging. This trend allows for optimized performance and improved compatibility with specialized circuits.

Improved Power Handling: The demand for higher power densities and efficiency in power electronics has driven the development of inductors capable of handling larger currents. Manufacturers have introduced inductors with improved current ratings, lower DC resistance, and higher saturation levels. These advancements enable inductors to handle higher power levels while maintaining stability and reliability.

Adoption of Advanced Manufacturing Techniques: In recent years, advancements in manufacturing techniques, such as automation, precision assembly, and advanced winding methods, have improved the consistency, quality, and cost-effectiveness of inductor production. These techniques have enabled manufacturers to meet the increasing demand for inductors while ensuring reliable and consistent performance.

Environmental Considerations: Environmental regulations and sustainability concerns have influenced the development of more eco-friendly inductors. Manufacturers have been exploring alternative materials and production methods that minimize the use of hazardous substances and reduce environmental impact. This includes the adoption of lead-free soldering processes and the use of more recyclable materials.

The interaction between market demands, technological advancements, and suppliers has led to a shift in the inductor landscape. Manufacturers have been collaborating with suppliers to source advanced materials, refine manufacturing processes, and develop innovative solutions. The market demand for smaller, more efficient, and specialized inductors has influenced the choices of materials, design techniques, and customization options offered by suppliers.

Overall, the developments in inductor manufacturing over the last decade have focused on meeting the evolving needs of the electronics industry, including miniaturization, enhanced performance, customization, and environmental considerations. These advancements have facilitated the integration of inductors into a wide range of applications and contributed to the progress of electronic devices and systems.